LCC JAW CRUSHER

PRODUCT PRESENTATION

FEATURES & BENEFITS

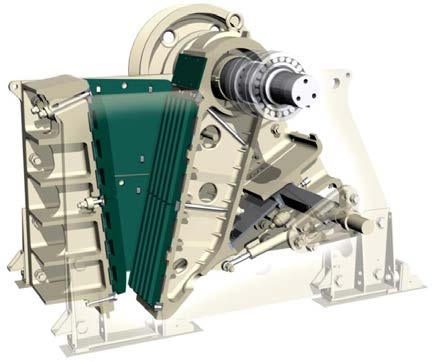

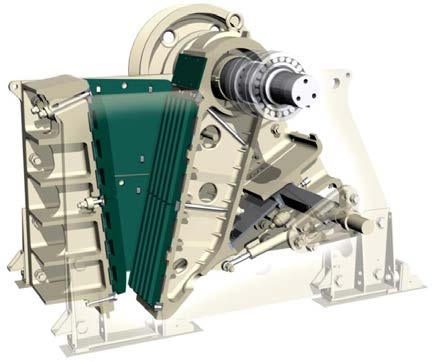

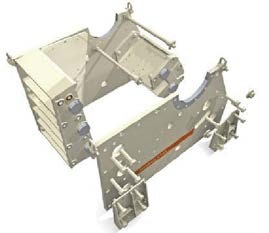

Luckcome LCC series jaw crushers are based on a revolutionary modular, non-welded frame construction.This design brings the results of the highest possible fatigue strength, excellent reliability and numerous mounting possibilities. This, combined with high-quality cast steel components and premium spherical roller bearings, means exceptionally high crusher availability, cost-efficient crushing and low cost per ton. Whatever your crushing needs-from hard and abrasive rock to various recycling materials-you’ll find the optimum solution with the LCC series jaw crushers.

FEATURES & BENEFITS

World-Class Craftsmanship and Materials

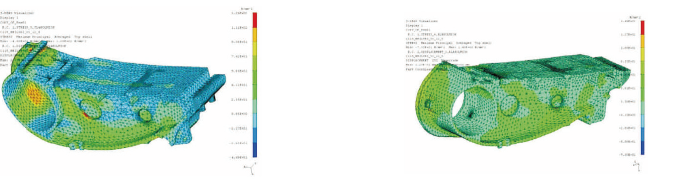

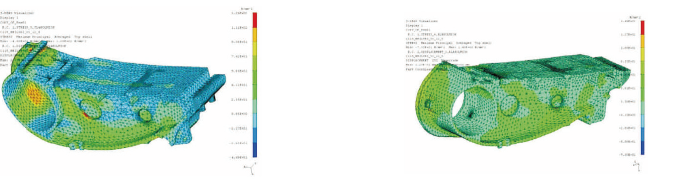

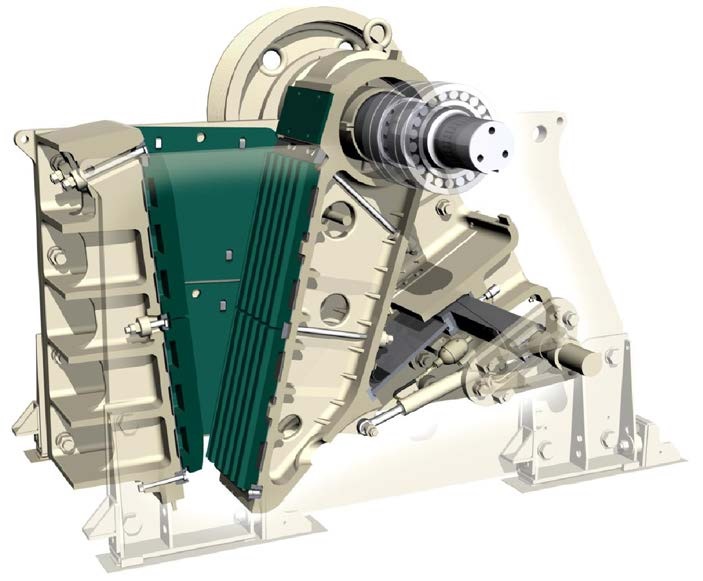

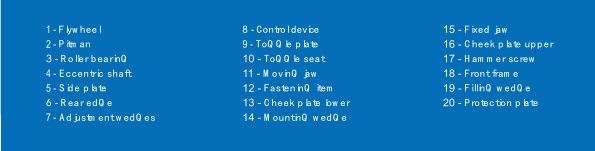

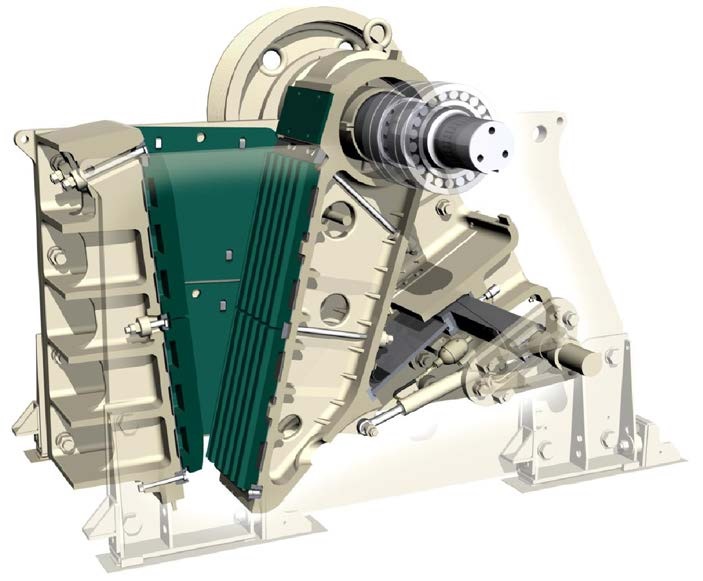

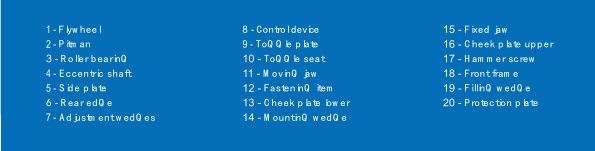

A uniquely modular, non-welded frame construction is a state-of-the-art design with two hot-rolled steel side plates joined to high-quality cast steel frames through robust, precision machined bosses secured with bolts. The pitman is made of high-quality cast steel and is propelled by two massive cast flywheels. A verylarge eccentric shaft forging and four large spherical roller bearings that are all of the same size ensure the greatest reliability. The grease-lubricated bearings are kept free from contamination by means of wellproven labyrinth seals. The single piece cast steel frame bearing housings ensure a perfect fit to the crusher frame. They also prevent unnecessary loads to the frame bearings.

Designed for Your Crushing Costs Down

All LCC series jaw crushers are equipped with a proven, rugged and fast wedge setting adjustment system. The system is especially effective at clearing the crusher’s cavity should it stall under load due to interruptions in the supply of electric power. Rubber dampers and stoppers effectively decrease crushing loads to the foundation by absorbing peak shock loads and allowing the crusher to move vertically and longitudinally. An integral motor base is mounted on the mainframe of the crusher, thereby reducing the need for space and excessively long v-belts.

The Right Cavity Design

LCC Series jaw crushers are literally designed "from the inside out" because the cavity is the heart and only purpose of the jaw crusher.

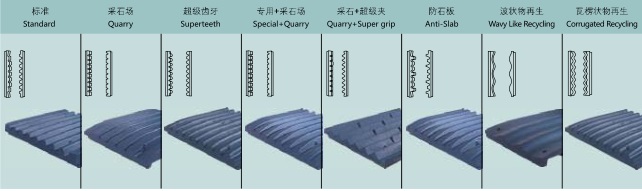

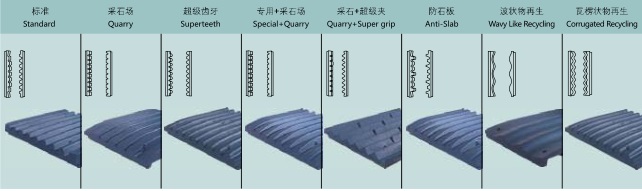

The right feed opening width to depth ratio ensures minimum blockage and eliminates unnecessary height from the crusher.LCC Series jaw crushers have a large eccentric throw coupled with a steep toggle plate angle that magnifies the effective stroke at the crusher discharge. The large stroke, combined with the right speed, flywheel inertia and high vailable crusher power result in truly high crusher performance. Many types of jaws have been

developed, the tooth profiles as well as the thickness of the jaws are optimized and combined with the right manganese steel alloys to maximize throughput and minimize operating costs.

Easy to Automate

Easy to Automate

Due to their hydraulic setting adjustment, LCC Series jaw crushers can be fully integrated into plant automation systems.The setting of the crusher can be changed from an electrical cabinet next to the crusher, or from the operator's room, all at the touch of a button, and even while the crusher is idling. The lubrication of the crusher's bearings can also be automated. Bearing temperatures, crusher speed and cavity levels can all be measured and fully integrated into plant automation systems.

INSTALLATIONS & USAQE

INSTALLATIONS & USAQE

Surface Installation

Due to their overall space requirements, LUCKCOME LCC Series jaw crushers are an ideal choice for the replacement of existing double and single toggle jaw crushers. Foundation loads, when compared to those of older version jaw crushers, are less and therefore modifications to the existing foundation are rarely required. An increase in plant capacity, the ability to process a coarser feed and the ability to produce a finer product are common benefits when replacing old version jaw crusher of comparable size.

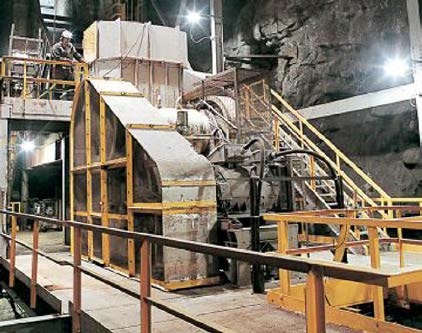

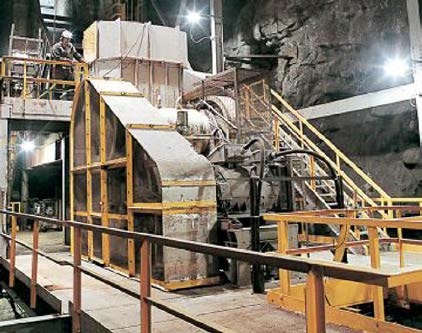

Underground Installation

Underground Installation

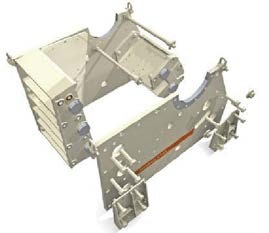

Transportation of LCC Series crushers to underground installations is greatly simplified as each major component can be handled individually,

and final crusher assembly is done underground. This has direct impact on mine planning that often results in considerable time and cost savings. Final assembly underground requires typicallifting facilities and a surprisingly short amount of time.

Mobile Plants Installation

LCC Series jaw crushers can be installed on track-mounted, full mobile crushing plants, and has also on wheel-mounted and semi-mobile plants. Mobile crushing equipment offers considerable benefits, including less quarry traffic, less dust, noise and exhaust emissions.

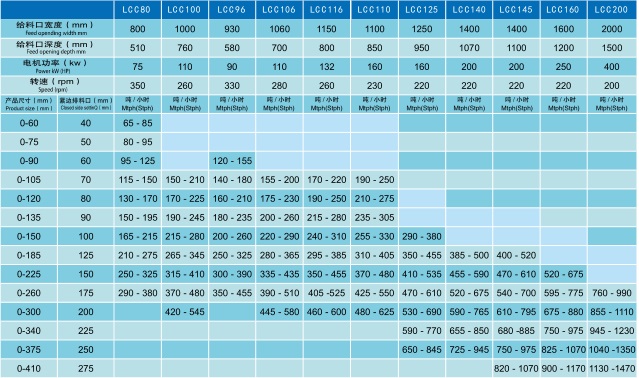

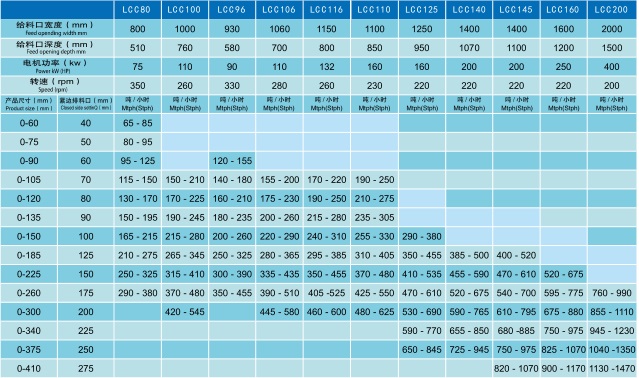

The above figures represent through the crusher capacities, which are based on a feed material with an average specific gravity of 2.7t/m³, a maximum feed size that will enter the crusher without bridging and material finer than the crushers closed side setting removed. The capacities may vary depending on the

feeding method and on feed characteristics such as gradation, bulk density, moisture, clay content and crushability.

Measurement of the crusher’s closed side setting varies depending on the jaw profile that is being used and has an impact on the crusher’s capacity and product gradation. The following factors will enhance crusher capacity and performance:

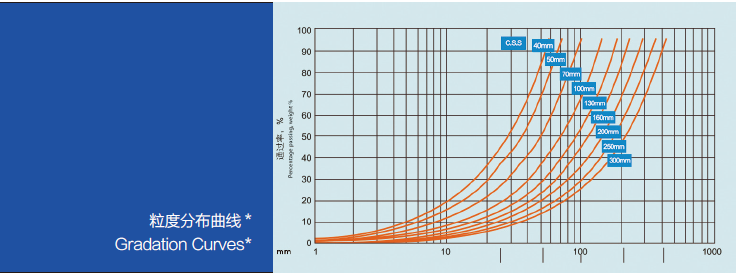

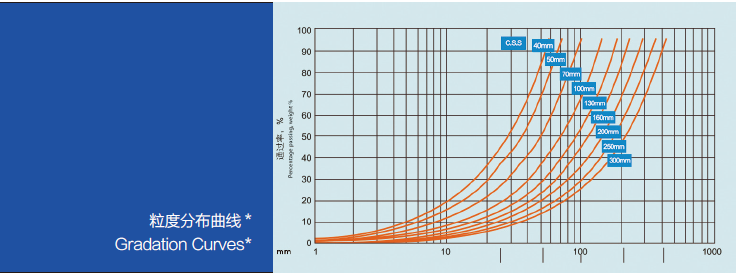

Gradation Curves *

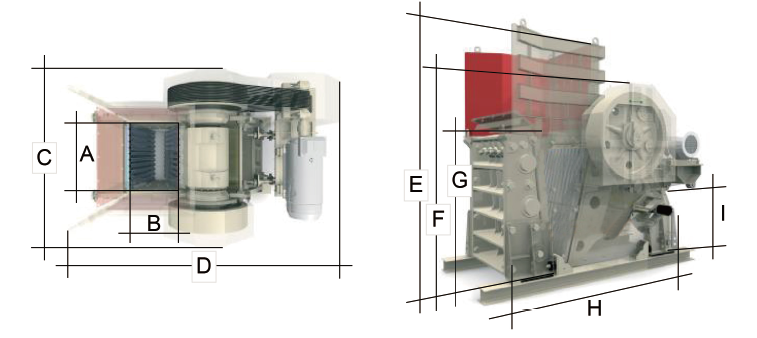

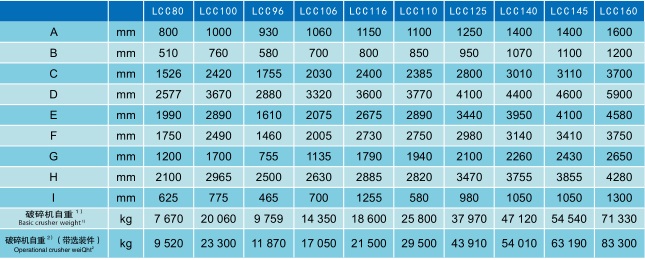

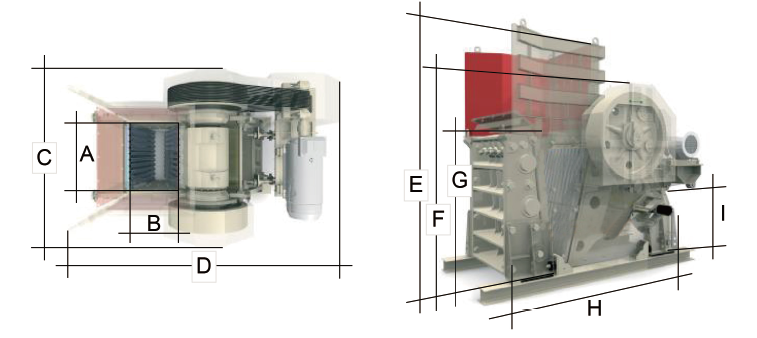

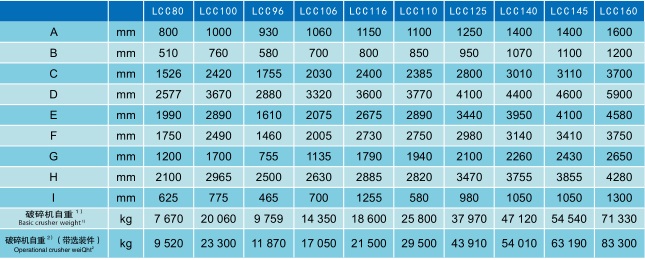

Dimensions & Weights

Dimensions & Weights

(1)Crusher without options

(2)Crusher, hydraulic setting adjustment, flywheel guards, integral motor support, feed chute, automatic grease lubrication system, and typical electric motor.